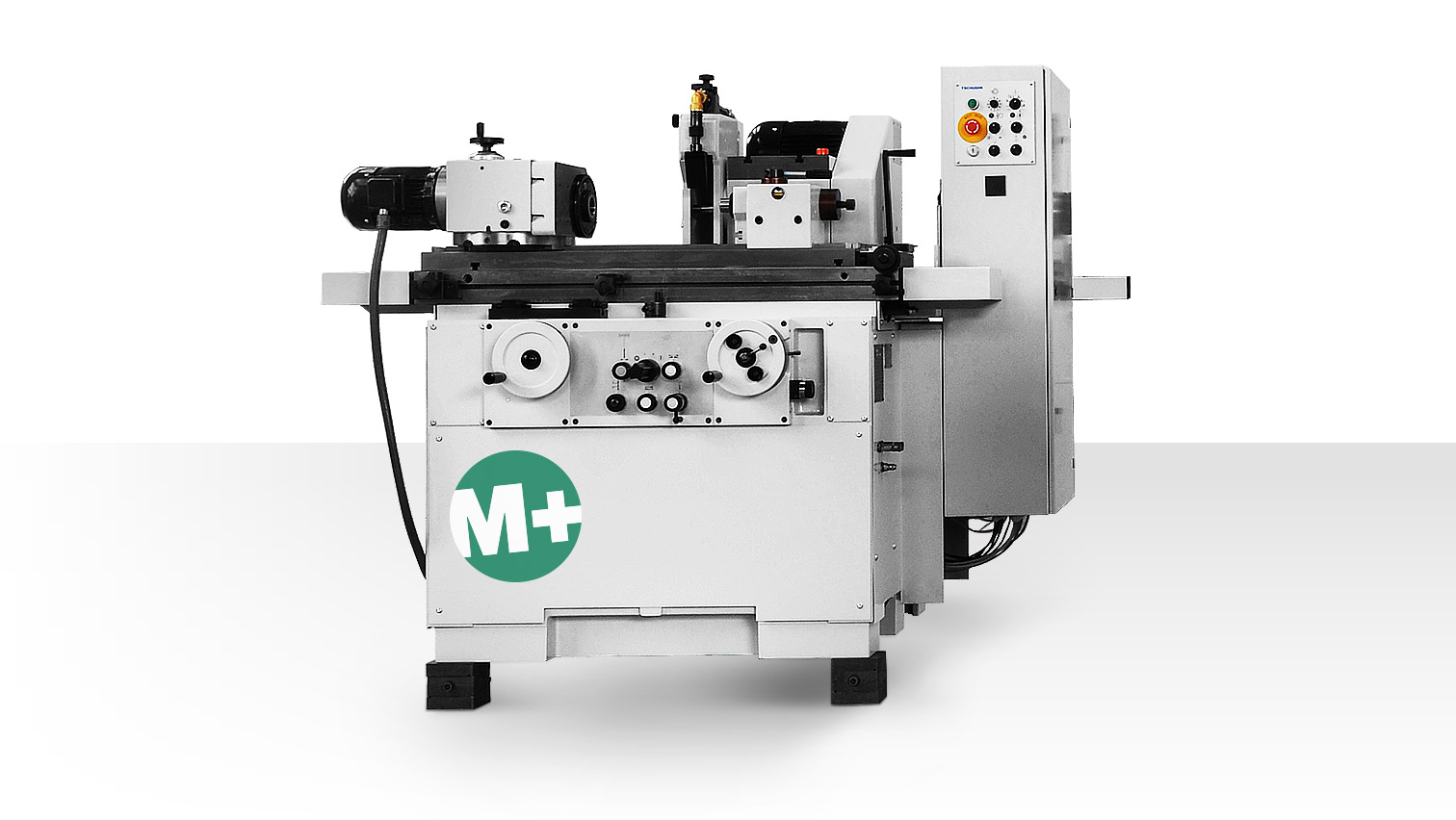

HTG 310

The precision grinding classic

HTG 310: Compact cylindrical grinding machine for individual part and small series production

The HTG 310 is a classic among precision grinding machines and enjoys an excellent reputation as a reliable, durable and high-precision solution for demanding applications in the automotive, aerospace, medical technology and more. Its compact and robust machine body as well as the high-quality guides contribute to vibration dampening and ensure high machining accuracy. The machine is equipped with effective cooling and lubrication systems that improve the thermal stability and service life of the machine and ensure consistent machining quality.

Workhead

- With MK5 (roller bearing)

- With MK4 (hydrodynamic bearing): very precise concentricity <= 0.001 mm<= 0,001mm

- Also available with MK4 high precision: high precision concentricity <= 0.0005 mm<= 0,0005mm

Hydrodynamic grinding wheelhead

- Good damping properties

- Self-centring with high-precision concentricity

- Long service life

Slide guides

- High process stability thanks to high-precision V and flat guides

Grey cast iron machine bed

- Warp-free, thermally stable and vibration-damping

- Cubic, heavily ribbed

Tailstock MK3

- Adjustable quill setting pressure

- Manual or automatic operation (optional)

- Taper correction +/- 0.02 mm (optional)

The heavily ribbed machine base made of high-quality, repeatedly stress-free annealed gray cast iron ensures maximum rigidity and damping. The entire grinding cycle can be preset and thus simplifies individual part and small series production.

Good accessibility to all functional areas shortens changeover times and makes maintenance easier. A large selection of application-oriented accessories expands the possible applications and enables the processing of even complex workpieces.

Technical specifications

Main specifications

|

|||||||||||

Workpiece headstock

|

|||||||||||

Grinding wheelhead

|

|||||||||||

Longitudinal slide

|

|||||||||||

Tailstock

|

|||||||||||

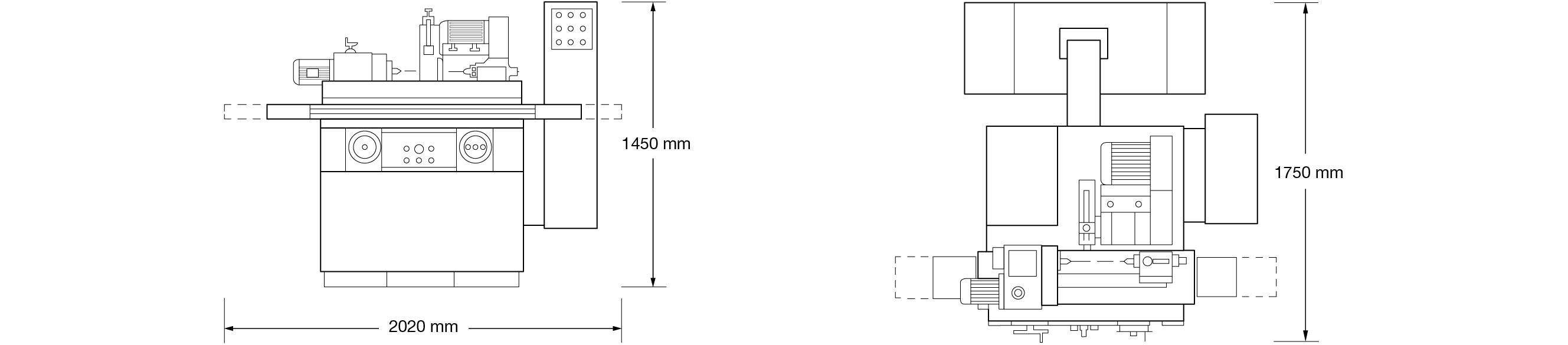

Space requirement (WxHxD)

|

|||||||||||

After Sales

To help our customers get the most out of our machines, we offer them customized after-sales services. These include our Aktiv+ package for preventive maintenance, as well as training the operating personnel on how to use our machines. Regular staff training ensures that the machines are always used optimally and that smooth operation is maintained, even with new employees. If needed, training can also be conducted on-site at the customer's location.

Interested in this machine?

Contact Us!

Please fill out the form below completely. The more information and contact options you provide, the faster and more effectively we can respond to your message.