MBF 453U

Universal machine with a mind of its own

MBF 453U: CNC universal machine for high-precision internal and external cylindrical grinding

Our universal machine for high-precision internal and external cylindrical grinding, based on the MaiBase platform, is the ultimate solution for single-piece, small-batch, and large-scale production. It is designed to produce small to large workpieces that meet exceptionally high standards of accuracy, surface finish, and form tolerance.

- 19˝ LCD color screen with touch function

- M.+M. Mai software with a GUIDE for easy and guided program creation at the workpiece

- IPC operating system: Windows 10 IoT

- Handheld panel with axis and speed selection switch

- FEM-optimized mineral casting bed for maximum stability and durability

- Mechanical separation of the machine and peripherals for thermal stability and minimization of vibration influences

- Supports workpiece weights up to 100 kg

- MK3 and MK4

- Stroke of 20 mm (optional 60 mm and 120 mm)

- Adjustment range of +/-30 μm

- Pneumatic and hydraulic lift-off

- Suitable for applications with stationary or rotating spindles

- Speed range 1 – 1,000 rpm

- Roundness accuracy ≤ 1 μm (optional ≤ 0.5 μm)

- Oriented spindle stop

- Available in MK4, MK5, and MK6

- Linear guide for X-axis, low maintenance, highly accurate

- Low-wear sliding guide for Z-axis

- Optical measuring systems in X and Z axes

- High dynamics with speeds up to 8 m/min in both Z and X axes

- Excellent overview of the grinding process

- Centrally and easily accessible interfaces for table setups

- Thoughtful accessibility for cost-effective maintenance and service

- Optional automatic door opening

- Cantilevered up to 100 Nm

- Up to 100 kg between centers (depending on the variant)

- Significant reduction of idle times through quick swiveling of the fully automatic grinding spindle head

- Highest positioning and repeatability accuracy due to the use of a Hirth gear

The MBF 453U is based on our MaiBase system platform for custom-designed universal and production cylindrical grinding machines, embodying the core concept of "High production performance – compact design – economical price" perfectly.

Understanding that no grinding task is the same as another, we have purposefully combined superior individual components in the MBF 453U to create a tailored solution for both straight and angular plunge grinding.

FANUC Oi-F Plus

Thanks to its powerful hardware, its standard 2 MB part program memory and its versatile functions for customer-specific adjustments (FANUC Picture, Macro Executor, C Language Executor), this CNC control is ideal for demanding grinding tasks and a guarantee for high-quality workpieces. The in-house developed Fast Cycle Time Technology ensures reduced cycle times.

- Simple and intuitive interaction via the screen

- Easier navigation and operation of the programs

- precisely tailored to the machine configuration and grinding processes

- innovative features not available in standard solutions

- Operating instructions and accessory documents available on the controller

- Minimize downtime and quickly resolve problems

- Cost savings through reduced on-site service calls

- such as grinding time, dressing time and workpiece changing time (only for machines with integrated loader)

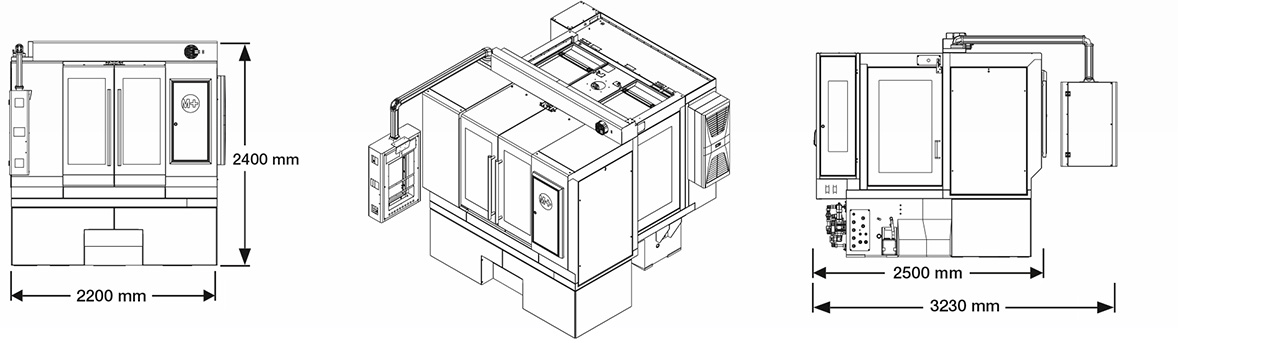

Technical specifications

Technical specifications

|

|||||||||||||||||

Grindable workpiece diameter

|

|||||||||||||||||

Grinding wheelhead

|

|||||||||||||||||

Workpiece headstock

|

|||||||||||||||||

Tailstock

|

|||||||||||||||||

Longitudinal slide

|

|||||||||||||||||

General data

|

|||||||||||||||||

After Sales

To help our customers get the most out of our machines, we offer them customized after-sales services. These include our Aktiv+ package for preventive maintenance, as well as training the operating personnel on how to use our machines. Regular staff training ensures that the machines are always used optimally and that smooth operation is maintained, even with new employees. If needed, training can also be conducted on-site at the customer's location.

Interested in this machine?

Contact us!

Please fill out the form below completely. The more information and contact options you provide, the faster and more effectively we can respond to your message.