M.+M. Mai machines:

Cylindrical grinding in perfection

Whether conventional or CNC controlled: M.+M. Mai cylindrical grinders process even complex workpieces with outstanding accuracy. They are the ultimate solution when it comes to series production of high-precision workpieces for the automotive, aerospace and aerospace industries or medical industry.

Their rigid main structures, high-precision guides, hydraulically operated slide adjustments and hydrodynamically mounted grinding spindles guarantee maximum precision and operational safety.

- With MK5 (roller bearing)

- With MK4 (hydrodynamic bearing): very precise concentricity <= 0.001 mm

- Also available with MK4 high precision: high precision concentricity <= 0.0005 mm

- Good damping properties

- Self-centring with high-precision concentricity

- Long service life

- High process stability thanks to high-precision V and flat guides

- Warp-free, thermally stable and vibration-damping

- Cubic, heavily ribbed

- Automatic loading and unloading of workpieces (optional)

- Open loader interface enable customer-specific solutions

- Adjustable quill setting pressure

- Manual or automatic operation (optional)

- Taper correction +/- 0.02 mm (optional)

CNC-controlled universal and production cylindrical grinding machines

MB Series

with Fanuc control

- Model MBF 453U

- Model MBF 452U

- Model MBF 450A

- Model MBF 450

- Model MBF 460

- Model MBF 460A

CNC-controlled

cylindrical grinding machines

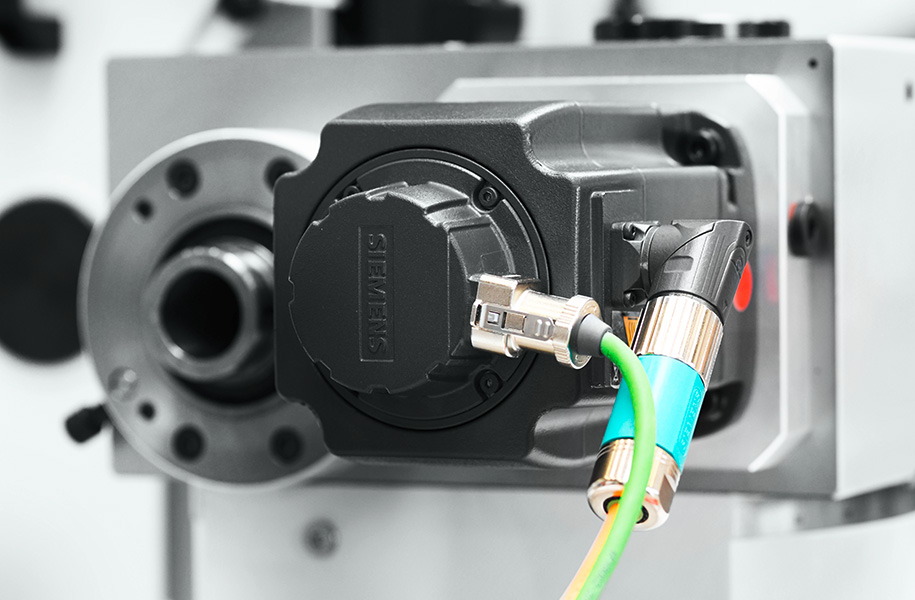

Series TB

with Siemens control

- Model TBS 440

- Model TBS 450

- Model TBS 450A

- Model TBS 460

- Model TBS 460A

- Model TBS 640

- Model TBS 650

- Model TBS 650A

- Model TBS 660

- Model TBS 660A

Series TB

with Fanuc control

- Model TBF 440

- Model TBF 450

- Model TBF 450A

- Model TBF 460

- Model TBF 460A

- Model TBF 640

- Model TBF 650

- Model TBF 650A

- Model TBF 660

- Model TBF 660A

Conventional

cylindrical grinding machines

Series HTG

hydraulic

- Model HTG 310

- Model HTG 610

- Model HTG 610U

Repair, retrofit

& brokerage

for the following models:

- HTG 410, HTG 412

- HTG 420, HTG 422

- HTG 430, HTG 432

- HTG 440, HTG 442

- HTG 610, HTG 612

- HTG 620, HTG 622

- HTG 630, HTG 632

- HTG 640, HTG 642

After sales services

To help our customers get the most out of our machines, we offer tailored after-sales services. In addition to our Active+ package for preventative maintenance and servicing, this also includes the instruction of operating personnel. Regular training ensures that the machines will always be used optimally. Training courses can also be made on site.

- Repair of components such as workpiece headstock

- Replacement of wear parts, measurement / functional check

- Inspection and cleaning of guides and lubrication systems

- Spindle bearings, seals, belts

- Clamping devices

- Pullers

- Tools

- Filter systems

- Machine overhauls

- Production optimization

- Technical and electrical support

- Support via phone